Jun. 28, 2024

After the pre-use treatment, some matters must be paid attention to during use, otherwise the early results will be wasted.

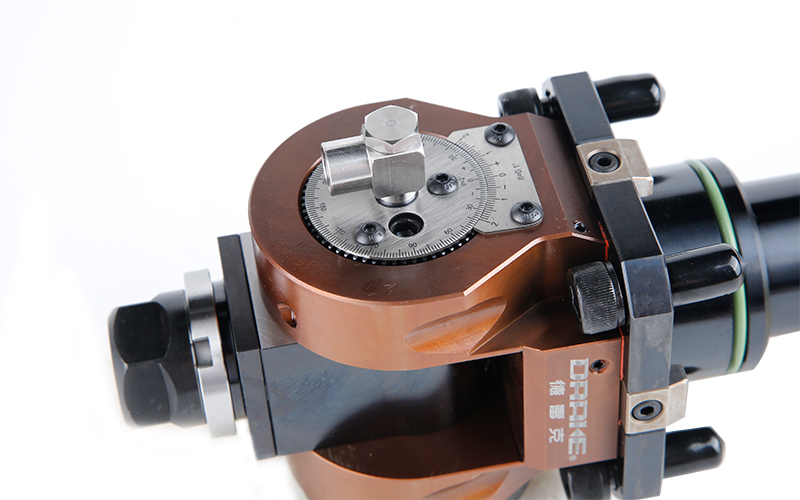

1. Appearance maintenance After completing the work every day, be sure to clean the iron filings on the power head push rod, drill chuck or multi-axis drilling head, tool, etc. to keep the appearance of the power head clean.

2. Lubrication maintenance After the cleaning work is completed, remember to add an appropriate amount of lubricating oil to the push rod and drill chuck.

3. Motor maintenance Clean the motor regularly, check the position of the electrical device, and ensure that the electrical device is fixed, safe and tidy.

4. Maintenance of parts Regularly check the tightness of screws and bolts, the tension of the belt, whether the protective cover is intact, and whether the hydraulic damper is leaking oil.

The power tool holder needs more maintenance in the later stage of use

Precautions for the later maintenance of the power tool holder When the power head fails, do not disassemble it randomly.

Be sure to find the cause before taking the right medicine. If you do not understand the reason,

be sure to contact the manufacturer by phone and repair it under the guidance of the manufacturer;

if you do not know how to repair it, you can return to the manufacturer or agent for repair.

And replace the "overage" parts and damaged and consumed parts of the power head in time.

Under normal use, the power head should be monitored and repaired once a year, and never let the power head work with problems.

When the power tool holder is not in use, it must be cleaned, coated with anti-rust oil, and placed in a dry place.

Doing the above work can extend the service life of the power tool holder to a certain extent and maximize its use value.